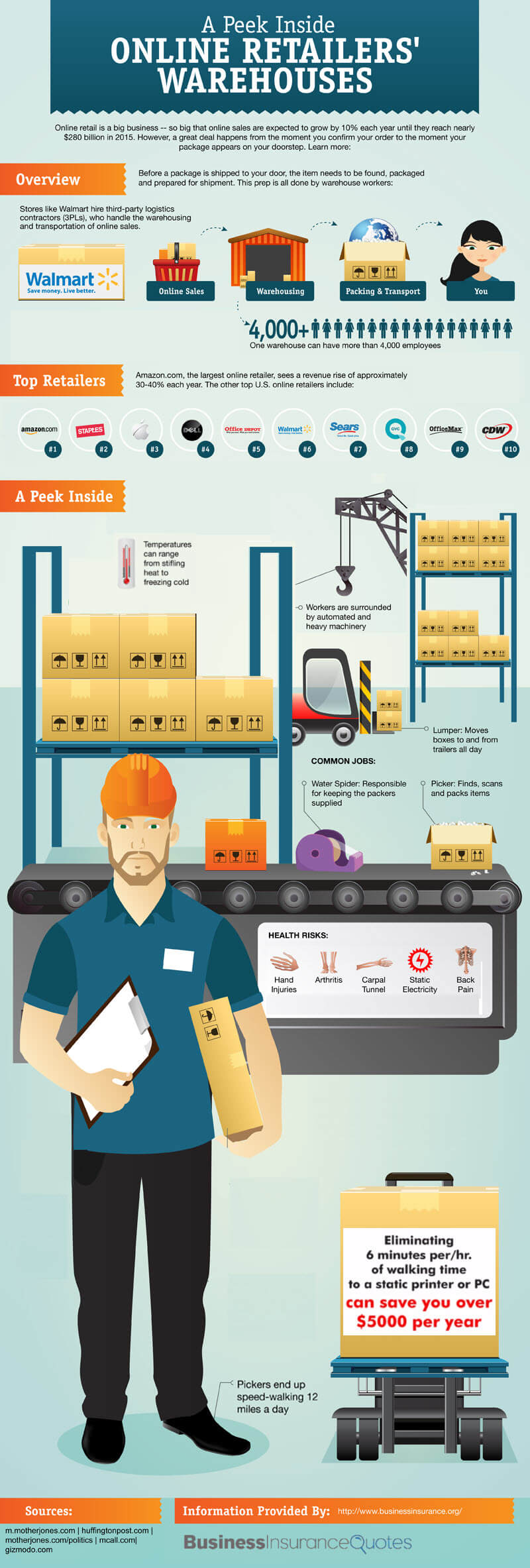

While the public will never see the inside of a warehouse, people are diligently working to ship products at a rapid pace. It is estimated that online sales will be $280 billion dollars in 2015. Everything happens because of warehouse workers. It is important to look more closely at this segment of the business and the people who work in the warehouses, receive products, do the ordering picking and ship.

- +1 (781) 935-3450

sales@newcastlesys.com