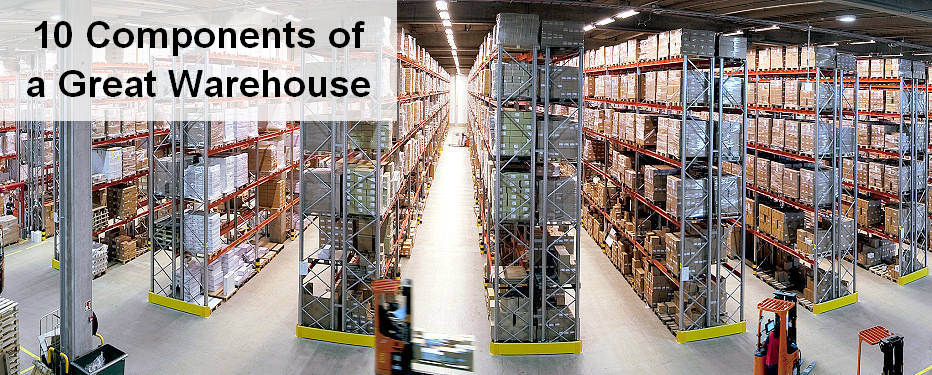

The perception that many have of the simplicity of warehouse operations merits consideration. How simple is it? We receive goods, put them away, pick them upon order, ship, and then maintain the overall operation. On it’s face it appears simple. Yet, let a novice manager in training step into the shoes of an existing warehouse manager and they may soon find themselves overwhelmed.

- +1 (781) 935-3450

sales@newcastlesys.com