Each year, warehouses face a massive surge in activity lasting several months due to holiday shoppers filling up online and physical shopping carts. This “peak season” typically begins in October and lasts until sometime in January, allowing for the high volume of post-holiday returns.

During this period, warehouses and distribution centers are forced to ramp up operations and meet an increasingly long list of demands. This has become challenging in recent years thanks to supply chain disruptions, labor shortages, and rising consumer demands for fast delivery times and personalized service.

Peak season isn’t easy for most businesses. According to a recent Supply Chain Dive survey, three out of five respondents (59%) say they expect their upcoming peak season to be challenging. Fortunately, there are many things your business can do to make this holiday season your best yet. Here are some tips to increase efficiency now as you start preparing for peak season.

1. Start Planning Early

Ideally, the time to begin planning for peak season is immediately after the last one ends. After all, this is when everything that just happened is still fresh in your mind. But, the challenges you face during one peak season may not be the same as the last one, so it’s important to carefully analyze the data and trends. When you do, ask yourself these questions:

- How has peak season activity changed over the past several years?

- What challenges did you face over the past peak season?

- Did you identify any opportunities to improve operations?

- Have you made any operational changes since the last peak season that would impact your next one?

Although inventory forecasting is never completely accurate, you’ll want to use the data and insights available to improve your inventory management. For example, even with lower inflation levels, 43% of retailers say they plan to order less stock for peak season this year compared to last year.

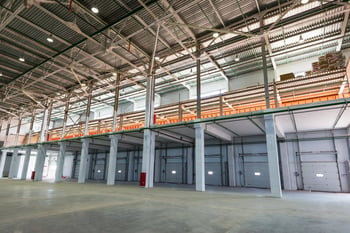

2. Optimize Your Warehouse Layout

To ensure you don’t have bottlenecks during your peak season operations, now is the time to take a close look at your warehouse layout. It’s important to focus on each area of your warehouse (shipping, receiving, storage, picking, packing, etc.) as well as look at the big picture.

To ensure you don’t have bottlenecks during your peak season operations, now is the time to take a close look at your warehouse layout. It’s important to focus on each area of your warehouse (shipping, receiving, storage, picking, packing, etc.) as well as look at the big picture.

For example, a well-designed receiving area will move items quickly into the warehouse to their inventory storage locations. Inventory should be stored in the most optimal way possible. The high-turnover products are usually placed closer to the picking and packing areas. If you can make some major adjustments, it may make sense to free up room in your warehouse by adding bins, using vertical space, or creating more narrow aisles.

Finally, consider how you will be using technology in your warehouse. For example, using mobile workstations throughout the warehouse can reduce the need for office space and centralized printing stations.

3. Hire & Train More Staff

Labor shortages and high turnover rates have plagued the warehousing industry over the past several years. However, you’re going to need additional staff to be successful during peak season. With more orders coming in, you’re going to need more bodies to handle the order fulfillment and inventory management. Some of the ways you can approach staffing include:

Labor shortages and high turnover rates have plagued the warehousing industry over the past several years. However, you’re going to need additional staff to be successful during peak season. With more orders coming in, you’re going to need more bodies to handle the order fulfillment and inventory management. Some of the ways you can approach staffing include:

- Offer bonus incentives for current employees to improve attendance and performance.

- Consider sign-up bonuses for short-term and temporary workers.

- Think of ways to make work interesting and fun, like free snacks, raffles, and prizes for workers.

As you bring in more workers for peak season, make sure to give them adequate training. In fact, the same peak season training should be provided to your current associates to ensure everyone is on the same page.

Find out who has worked through peak season with your company before and consider making these associates trainers or team leaders. Create training materials or programs that are engaging and educate your workers about your specific processes and expectations.

4. Leverage the Right Technology

If you manage a warehouse during peak season, you understand that efficiency and communication are critical components to your success. Fortunately, your business can use a variety of technology solutions to boost productivity, reduce errors, and even cut costs. Some examples of useful warehouse technology solutions include:

Warehouse Management System (WMS) — A WMS can help with inventory management, order fulfillment, materials tracking, billing, and much more.

Warehouse Management System (WMS) — A WMS can help with inventory management, order fulfillment, materials tracking, billing, and much more. - Barcodes and RFID Tags — Using barcodes and RFID tags on products, pallets, bins, and machinery allows your warehouse to have more visibility throughout the process.

- Automated Picking Tools — Automation tools can help your human workers with picking and packing operations during the busiest time of the year.

- Mobile-Powered Carts — Mobile computer workstations and printer carts allow workers to take their technology with them throughout the warehouse and double their productivity.

- Wearable Technology — Wearable technology like wireless headsets can help workers with picking operations as well as machine maintenance and repair operations.

5. Streamline Your Returns Management

Handling returns has become an essential part of doing business. Consumers have increasingly high standards, and return rates during peak season seem to be higher compared to the rest of the year. During the first week of January 2021, UPS handled a staggering 8.75 million returns, a 23% increase from just a few years prior.

If your business isn’t prepared to handle the reverse logistics process efficiently during peak season, it is risking significant revenue losses in addition to eroding consumer trust. Fortunately, many of the technology solutions you apply to your fulfillment processes will work here as well.

Peak season may be another few months away. But any business in the warehousing or logistics industry can’t wait until the last minute to prepare for the surge in consumer shopping and fulfillment activity. The time to begin preparing and putting the right solutions in place for your warehouse is now.