Among many of the challenges that 2020 forced so many businesses to solve was how to not just create a direct-to-customer fulfillment operation but to optimize it and standardize the processes enough to make it seem like less of the scramble that it was when all of this started almost a year ago. One specific process that was a common challenge for many businesses in 2020 was the Picking Process.

Why is Picking Such a Challenge?

Looking up and down the list of core processes that most warehouses are dealing with on a daily basis – Receiving, Inventory/Putaway, Replenishment, Picking, Packing, Shipping – Picking is the one process with the most variation based on the type of business being supported or the mix of products involved.

Looking up and down the list of core processes that most warehouses are dealing with on a daily basis – Receiving, Inventory/Putaway, Replenishment, Picking, Packing, Shipping – Picking is the one process with the most variation based on the type of business being supported or the mix of products involved.

If your facility was shipping exclusively to distributors or retails sites before 2020, then you probably had a smooth-running process that involved picking of cases, and/or the filling of totes or bins that were packed up with others for delivery to individual stores or locations. But when 2020 happened and all the traditional retail outlets were either shut down or had their operations severely curtailed, it became paramount to find a way to deliver products directly to customers.

But the process of picking 160 of the same frying pan into 20 different totes to go to 20 different stores as their inventory for the week is VERY different than putting those 160 frying pans into 160 different boxes – which might be 8-10 different sizes, and sending them to 160 different addresses.

The consequential nature of the differences is self-evident when laying out the specifics.

- 20 totes vs. 160 boxes

- 20 tags/labels vs. 160 shipping labels and packing lists

- 20 commercial locations to ship to vs. 160 residential addresses

- Picking 8 or more at a time vs. Picking as few as ONE at a time.

Whatever picking process being used BEFORE is no longer going to work for the new process of shipping direct to customers. Our assumption is that many businesses may have started out this way when the pandemic hit, but then quickly learned that the sorting and packing processes involved of getting all the picked items into the right order for packing took a LOT of space, generated very high and wasteful labor costs and also ended in misery for many customers who were hurt by the mistakes made in the chaos this would create.

If you haven’t worked out your best approach to picking yet after 2020, then now is the time to do so. Here are a few basics of different picking methods that will help restore order. The one that works best for your business will depend on your mix of SKUs, industry, customer expectations, etc.

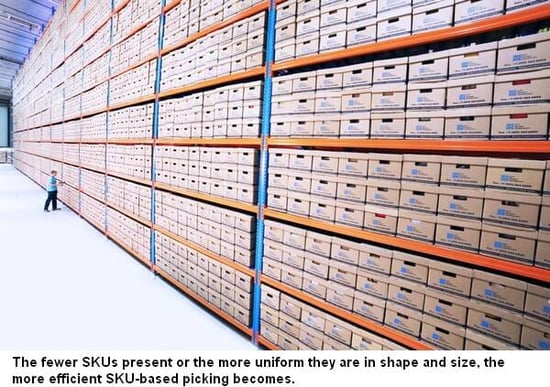

SKU-Based Picking

SKU based picking has a LONG list of disadvantaged for many facilities, though it was perhaps what most who were new to the direct to customer fulfillment were doing when the pandemic hit last year. In general, it works by providing the Picker a list for EACH ORDER to head out into the picking aisles and find the items needed. It works best in facilities with fewer SKUs which means fewer locations for workers to become familiar with. However, it can be optimized if their list shows items in order of the most optimized route through the racking.

PROS:

- Easy to implement for many existing facilities without major infrastructure or software changes

- Good option for low number of SKUs, especially if they include oversized or odd-shaped items.

- Works well for facilities where experienced employees know their way around the locations.

- Eliminates need for additional step for sorting and collating orders before packing. Picked orders can go right to packing.

CONS:

- Incredibly inefficient for any facility with large amount of SKUs. It would result in an unacceptable amount of walking for the Picking staff making it prone to higher inaccuracy.

- Requires staff to be well-versed on locations in aisles, harder to bring on new workers for peak periods.

Batch Picking

This method is a very common method in consumer retail operations and can support a higher volume of order and SKUs than SKU-based picking. In this method the products in your orders are split up on a picking list, and the workers go through the aisles in order with the locations, quantities and destination bin (on their picking cart) laid out so that by the time they have walked through all the aisles their cart is full of completed orders that can be delivered to packing.

Imagine a tall cart, with about 20 shelf locations on it, being pushed through the aisle and as the worker reaches a rack identified on their list they see that they need to pick 3 of a single item from a bin and put each one in three different locations on the cart (because of the 20 orders being picked, 3 ordered that item). They then move to the next location identified, pick the right amount, move on, and so on.

PROS:

- Removes the sorting step so that orders delivered to Packing are all sitting together with all of their required items.

- Allows for your aisles to be “one-way” to improve traffic

- Allows for random location assignments of SKUs which reduces picking errors (i.e. a single color of a men’s dress shirt might have 36 different SKUs to account for neck/sleeve size combinations, which leads to mispicks when their bins are all in the same rack

CONS:

- While it can be more efficient than SKU-based picking it has limitations in that it may require a lot of “exceptions” for large or odd-shaped items.

- It requires each worker to run the entire length of all the aisles for every batch of orders they pick, which adds an excessive number of footsteps (and the time required to make them). Especially hard for a much bigger facility with larger numbers of SKUs and the aisles needed to house them.

Zone Picking

This picking method picks up on the smarter location-driven aspects of Batch Picking and makes it more efficient by deploying workers to assigned zones where they pick only those items in their own zone, and then pass them along to another zone where other items from the order may be merged together with them. At this level, a modern Warehouse Management System (WMS) or similar software is required to make this work properly.

PROS:

- Far less wear and tear on workers who are limited to a smaller zone and thus hundreds less footsteps than if they were patrolling every aisle.

- Can support the easy deployment of pick-to-light systems or voice technology systems where efficiency can be accelerated even more with a hands-free process and bringing accuracy well above 99%.

CONS:

- Not as attractive for smaller facilities where the technology investment and additional planning may not have the quick ROI relative to some legacy methods.

- May also be less efficient for smaller order sizes (i.e. consumer retail averaging 2-3 items per shipment) as it requires multiple hand-offs through zones where there may be no picks required adding wasteful touches in the picking process.

Single Order Pick to Conveyor

This picking method involves not just the software investment of Zone picking, but also a large hardware investment in conveyor equipment and perhaps additional software for them (if automated). Basically, workers move totes along gravity conveyors through different zones and can use multiple technologies like Voice or Pick-to-Light to pull items from the bins above when the tote reaches that rack. A takeaway conveyor is positioned where the worker can push the tote or carton aside so it will get taken to Packing or Shipping as needed.

PROS:

- This method eliminates footsteps for the picker altogether and brings the totes/cartons to them.

- It’s an excellent option for a high-volume environment where cycle times are shorter than others

CONS:

- Can be a much larger investment to set up, especially if it involves automated conveyors and the software to route totes, etc.

- Requires sophisticated controls and software to optimize (i.e. for knowing when a tote can bypass a zone without the worker handling it, etc.).

Hybrid Batch Pick to Conveyor

In the final method we outline here, the workers may be picking from a zone that is fluid based on the current “wave” they are picking for, and at the end of the aisles, can literally “dump” the contents of their carts onto a conveyor which would take all the picked items to a tray sorter or other similar technology that would then deliver them with the rest of the order picked from other aisles to the Packing station. It’s incredible efficient for soft goods like clothing and other small retail businesses, as pickers can take advantage of the speed of Batch picking but without having to place each item in a separate bin.

In the final method we outline here, the workers may be picking from a zone that is fluid based on the current “wave” they are picking for, and at the end of the aisles, can literally “dump” the contents of their carts onto a conveyor which would take all the picked items to a tray sorter or other similar technology that would then deliver them with the rest of the order picked from other aisles to the Packing station. It’s incredible efficient for soft goods like clothing and other small retail businesses, as pickers can take advantage of the speed of Batch picking but without having to place each item in a separate bin.

PROS:

- Very efficient with picking rates extremely high

- Less investment required than some Pick-to-Conveyor options

- Retains high accuracy rates due to the random assignment of SKUs to bins.

CONS:

- Requires too many “exception” processes if you carry over-sized or odd-shaped items that can’t go on the conveyor

There More, But…

Technology and the evolution of processes in the typical warehouse mean that there are MANY other Picking “methods” that are out there. Today we wanted to share some of the most common and on a high level. If you have been struggling with evolving your fulfillment operations from the impact of the pandemic and the Ecommerce boom it created, it pays to get assistance analyzing your business model and processes to find the optimal process for your facilities. In MOST fulfillment operations, Picking is the largest cost in terms of manpower, so struggling to get this right means eating into your margins on a much larger scale than other processes might do.