Running an inefficient warehouse is a costly mistake no growth-focused business should endure. Unlike an under-performing salesperson or a poor quality product, the signs of an inefficient warehouse aren't immediately noticeable. When a salesperson consistently doesn't meet their sales targets, you know it is time to cut your losses.

When the returns of a product closely match its sales, you know you have a problem product on your hands. But how do you know when your warehouse is being run inefficiently? What are the symptoms of a warehouse in distress and how do you remedy those problem areas? If any of the following five symptoms are present in your warehouse, you just might have a problem on your hands.

Ongoing Order Errors

If your team is consistently fixing order errors, there is a good chance you have a warehouse problem. If your sales team spends more time taking phone calls regarding shipment mistakes than they do on converting new sales leads, it is time to take a long, hard look at how your warehouse is being run. Order errors lead to customer returns, which lead to overall dissatisfaction with your company. When your brand automatically has a negative connotation in your customer's mind, don't expect an increase in annual sales.

Payroll Mismanagement

If the hours allocated to your warehouse staff are consistently out-of-line with other departments, you might have a severe warehouse problem on your hands. An inefficient warehouse management structure can cause an increase in overtime wages as well as increased requests for time off or sick pay. A poorly run warehouse can lead to reduced staff morale and high employee turnover.

Warehouse Cleanliness

A disorganized warehouse is often a messy warehouse. The careless placement of inventory or warehouse machinery can lead to increased employee injuries and compensation claims. A slipshod warehouse management system can also lead to mismanaged inventory and customer order delays. When staff can't find products in a timely manner, backorders or cancelled customer requests can happen.

Inventory Shrinkage

Mismanaged inventory can also lead to unacceptable shrinkage levels. When there is no precise method of tracking all inventory, it is far too easy for items to go missing. Any warehouse visitor or employee can help themselves to product, knowing that the likelihood of their theft being discovered is slim.

Unnecessary Stock Counts

When your warehouse is mismanaged, you will frequently have inventory stock level problems. Your staff will over-order products that are already in stock or run out of items they didn't realize were hot sellers. This ongoing inventory mismanagement leads to unnecessary stock counts and a further increase in your warehouse payroll expenditures.

Once you know the signs of an inefficient warehouse, you are in a better position to fix the problem. One of the fastest ways to take a warehouse from out-of-control to organized is to implement a RFID tracking system. Radio frequency identification can be used to track everything from products destined for customers to the machinery you use in your warehouse. RFID technology offers real-time tracking for anything with an RFID tag attached to it and can significantly improve the way your warehouse is run.

When you develop a warehouse management system that includes RFID technology, you are able to manage the movement of your inventory and your employees in an optimal manner. No more under/over ordering of stock. No more paying for staff to conduct unnecessary inventory counts. Combine your reduced labor costs with your improved order accuracy and you have a winning equation for increased annual profits.

Incorporating RFID technology into your warehouse has other benefits in addition to increased savings. A RFID-enabled warehouse can be reorganized in a manner to allow for efficient movement of staff based upon inventory product type.

Using route optimization for the efficient movement of stock leads to improved inventory-metrics tracking and reduced order fill times. Efficient inventory tracking means product recalls can be attended to in a timely manner. Government compliance rates are also likely to increase when inventory is managed efficiently and all necessary documentation is filed as needed. Increased RFID automation leads to improved order accuracy and employee productivity, thereby elevating staff morale levels. Happy staff = less employee turnover.

If you are ready to put the power of RFID technology to work for your warehouse, pay attention to the following critical factors. Any RFID system you consider should integrate with your existing IT structure in the least disruptive way possible. A RFID system should have upgrade potential, both in software and hardware. You should be able to customize a RFID system to suit your business' specific needs and implementation speed should be a top priority for your RFID consultant i.e. offering a quick-and-easy tagging solution.

Once you understand how quickly a RFID system can correct your warehouse problems, putting those inefficiencies behind you is an easy decision. When increased productivity and profitability are a top priority, choosing RFID technology is a no-brainer.

Wasted Time and Wasted Steps

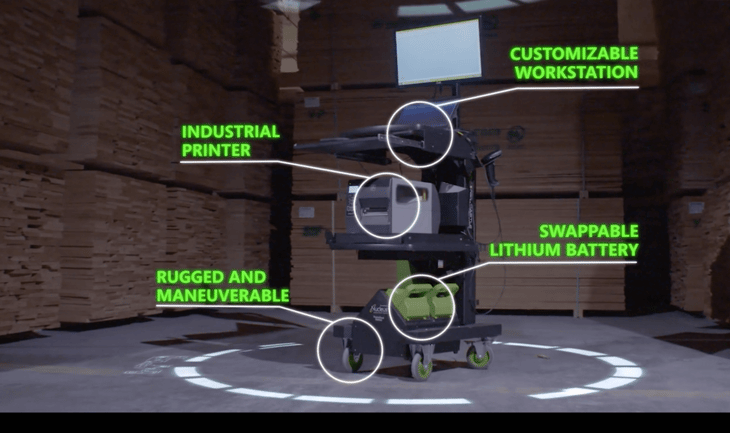

In order for employees to perform their jobs well and to be as productive as possible, they have to be equipped with the best tools. While they may be a team of exceptional workers with a great work ethic and a commitment to excellence, if they don’t have the proper equipment to do their jobs as efficiently, correctly, and easily as possible, they’ll never be able to achieve the same level of productivity as they would if they were equipped with the right state-of-the-art gear.

Utilizing wireless mobile workstations which can be both effortlessly wheeled across warehouse floors and easily maneuvered through snug aisle spaces instantly increases the amount of work a warehouse team can get done during any given shift.

Instead of continuing to have distribution personnel unintentionally wasting minutes (that quickly add up to hours) by frequently ambling back and forth to a stationary scale, printer, and computer in some corner of the space, they can instead have mobile powered workstations conveniently within arm’s reach.

Depending on layout and the number of dock doors, operators can spend upwards of 10-30 minutes per hour walking to and from a fixed station to enter data and print labels.

Simply reducing that motion can save one million dollars per year in labor for a company with 20 sites. It can increase receipts by 60%, eliminate overtime and the need for temporary workers. It can also eliminate a majority of errors by simply having all of the tools needed at the point of use.

Identifying waste in a facility is the first step to eliminating it. Some examples include unnecessary walking, pre-printing too many labels, bottlenecks and over processing of goods. While people and buildings are pretty well fixed, there are ways to better utilize the existing infrastructure and improve processes that will positively impact the bottom line.