The digital revolution that is transforming the broader economy continues to shape distribution models as well. Increasingly business distribution centers are evolving to serve customers directly in addition to their more traditional roles as distributors for retailers and resellers.

Larger businesses are leading the charge to transform their own warehouses into world-class distribution centers. However, smaller businesses find it difficult to match their efficiency and speed with similar facility and systems investments. This disparity begs the question, “How can smaller companies keep up?” The best way to stay relevant is to outsource these non-core functions to better qualified partners instead of trying to match what large companies are doing.

Once a slow-moving, low-tech, commodity-style industry, 3PLs are now at the forefront of much of the innovation in the warehouse business. As a result, they have become an efficient eco-system for bringing modern processes and eCommerce offerings to all business types.

A History of 3PLs

Prior to the 1980's transportation, warehousing, and IT were isolated at most companies, requiring separate management. Products were essentially handed off from one entity to another throughout the supply chain with no real collaboration or data sharing. However, the deregulation of the trucking industry in the same decade led to more trucking carriers as a result of reduced price controls and diminished collective vendor price setting. Subsequently, the market became more fragmented, allowing third-party companies to provide value-added logistics services.

As logistics needs to be expanded throughout the next decade, more companies made the leap internationally, expanding operations overseas. Favorable economic conditions in Asia incentivized US companies to shift their manufacturing overseas, necessitating more sophisticated supply chain management.

As logistics needs to be expanded throughout the next decade, more companies made the leap internationally, expanding operations overseas. Favorable economic conditions in Asia incentivized US companies to shift their manufacturing overseas, necessitating more sophisticated supply chain management.

An integrated approach to worldwide logistics for global companies followed next. Further technological advances allowed even more robust integration of business operations, materials procurement, inventory management, transportation, and order fulfillment. Now the use of 3PLs has become widespread, with over 85% of US Fortune 500 companies using 3PLs in recent years.

The State of Modern 3PLs

Today’s 3PLs use state-of-the-art technology to further improve supply chain visibility and lower logistics costs associated with carrying inventory. Predictive analytics allow greater information sharing and forecasting across teams and locations, improving operational efficiency. Better cooperation among shippers, customers, and administrative teams (like legal and HR) is key to business growth and sustainability. This level of integration is especially critical because customer expectations around shipping times are continuing to shorten.

Enhanced integrations allow vast networks to be connected seamlessly, providing real-time information across the organization. As a result, companies using 3PLs remain competitive by staying agile, minimizing supply chain interruptions, and predicting market trends more effectively.

3PL Advantages

1. Shared Costs

1. Shared CostsWhile 3PLs have numerous advantages over in-house warehousing and distribution, cost sharing is typically viewed as the main benefit. Labor, space, and transportation costs are shared, which is crucial for smaller operations and seasonal companies. Small businesses can forgo the expense of paying for unneeded warehouse space, equipment, utilities, and labor by only paying for what they use. This mitigates risk when product supply, demand, and availability ebb and flow. Keeping costs proportional to needs ensures consistent margins and enables better growth planning.

In addition to reducing cost, sharing warehouse space and distribution channels gives businesses access to additional capacity when it is needed. When an organization is in a period of growth, this allows for quick scalability. It also removes much of the risk of scaling up operations by not burdening organizations with costly capital investments to increase production. The result is that owners and managers can focus on their core competencies instead of solely concentrating their efforts on expanding the business and running the day-to-day operations. Furthermore, retaining customer-focused office functions like accounts receivable and chargebacks can be outsourced more easily while using an integrated 3PL solution, freeing up even more time for senior management to focus on strategic growth.

An organization typically enjoys a wider reach using a 3PL as well. With the ability to leverage global partnerships and infrastructure, businesses can produce and store products closer to customers. Keeping up with international laws, regulations, and currency exchanges then becomes easier across various international locations.

Increased supply chain transparency creates opportunities for greater operational efficiency. Improved access to and organization of the real-time data acquired at every step of the supply chain allows for more accurate forecasting. Without a 3PL solution, however, this type of big data analysis is out of the reach of many smaller companies.

Top 3PLs

When evaluating 3PLs, many organizations compare freight rates to get a sense of a solution’s competitiveness. While this is certainly one component of a comparative analysis, lifecycle logistics costs cannot be ignored either. The ideal 3PL will not only offer shared cost savings, but also align with a business strategy around total cost planning and procurement.

Leading 3PLs also utilize contingency plans to ensure that external factors like international trade relations do not affect supply chain continuity and shipping velocity. Integrated services allow for better management of reverse logistics and other supply chain intricacies to prevent costly disruptions.

According to recent data, the top US 3PLs by industry share are:

- H. Robinson

- XPO Logistics

- UPS Supply Chain Solutions

- Expeditors

- J.B. Hunt

Among these juggernauts, e-commerce has been the biggest driving force for growth, allowing the gross logistics revenue of these five combined to exceed $46B annually.

Current 3PL Trends

![]() While sole sourcing is an option, it is not typically practical. Instead, organizations tend to use multiple 3PLs that can work together to provide a more customized solution for achieving business objectives. Recent trends skew towards this concept of leaning on several 3PLs simultaneously to maximize the benefits they provide both individually and collectively.

While sole sourcing is an option, it is not typically practical. Instead, organizations tend to use multiple 3PLs that can work together to provide a more customized solution for achieving business objectives. Recent trends skew towards this concept of leaning on several 3PLs simultaneously to maximize the benefits they provide both individually and collectively.

Some companies choose to use two providers, naming one as the dominant 3PL and the other as a secondary 3PL. The role of the secondary provider is to keep an organization’s primary 3PL from becoming complacent. Requesting outside proposals every 3-5 years from other 3PLs ensures that both providers will continue to keep pace technologically with the rest of the industry. Soliciting proposals also keeps a company’s existing 3PLs honest when it comes to pricing changes.

2. Dominant 3PLsIn a dominant 3PL scenario, one provider performs most of the work while other 3PLs supplement these efforts with other specialized strengths. As additional needs are identified, the organization may continue to bring in other 3PLs to perform the increasing types of work. Ultimately, a network of top 3PLs working together creates a customized complete solution, which empowers an organization to fulfill its potential in the market.

3. Commodity 3PLsIn the case of non-specialized transportation, up to 10 different 3PLs can be rotated based on capability and need. This commoditized approach provides ultimate flexibility for an organization.

Customize Your Own Solution

The most important thing about getting started with a look at 3PL options for your business is that you can customize the type of support you want – from starting with a single, compartmentalized process up to taking over the whole show end-to-end in one of their facilities so that you don’t need one.

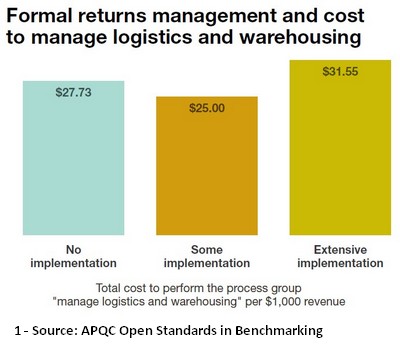

Returns processing is often a great place to start. Data from APQC shows that the cost of handling returns does not vary too much when outsourced to a 3PL. As the chart indicates, the cost per $1000 of revenue averages about 2.7% when doing it all in-house, versus a range of 2.5-3.2% for working with a 3PL to handle some or all of your returns processing. Given that there is less likely to be precise cost tracking for businesses doing it all in-house, my guess is that even this slight variation is exaggerated and the benefits are much greater than what the numbers already tell us.

Whatever your current take is on the use of 3PLs, for all but the most sophisticated retailers who have been doing this on scale for years, it makes sense to include them as part of your planning. Scaling for future growth, scaling back costs, relocating, etc. There is probably a process or two where you know it would be worth looking at a test to develop a good set of partners to rely on in the future.