Last week the Washington Post did some excellent work calculating a number of key statistics around the logistics of Santa’s big night of Christmas Eve (See “The Breathtaking Scale of Santa Claus’ Task on Christmas Eve - by Philip Bump”).

Everything from total miles covered, the number of possible routes, the weight and volume of the total number of presents and even the number of calories consumed via cookies left for St. Nick.

More than anything, it is possibly proof that Santa’s work must involve magic!

But it made us wonder about some other KPIs that come in the process before the big night of the 24th in the workshop itself.

How Many Footsteps Are We Talking About?

Just how many footsteps are those elves taking, and how many of them are wasted for lack of a lean process solution, like a cart? If we’re going to take a guess, we’ll need to consider the number of labels and the amount of product being moved around. Let’s do some math:

Just how many footsteps are those elves taking, and how many of them are wasted for lack of a lean process solution, like a cart? If we’re going to take a guess, we’ll need to consider the number of labels and the amount of product being moved around. Let’s do some math:

If Santa is bringing just one gift, a Rubiks cube, to the 537mm kids on his list, and if there are 12 per case, that would mean about 45mm cases – and labels – packed and stacked on 175,000 pallets (assuming 256 cases per pallet). So that’s a tad more than 45mm labels. We’ll assume Santa has been diligent enough to generate labels for the cases on the production line, but if the pallets are being labeled on the shipping dock and the labels are coming from stationary printers, we’ll assume the shipping elves are printing 30 labels at a time, one for each pallet that can fit into a 53 foot trailer.

That would mean 5,833 trailers with one trip to a printer for each set of unique labels. If the average distance between shipping bay and printer is 40 feet, a dock worker can end up walking almost 10 minutes per hour.

But Elves Take MORE Steps

But wait – elves are short! According to our sources, the average elf at the North Pole is just under four feet. A small human at 5’2” would have a stride length as short as 18”. For a 3’11” elf, that could mean a 14” stride, meaning the 10 minutes of walking a human would do could add another 3 minutes of walking every hour!

But wait – elves are short! According to our sources, the average elf at the North Pole is just under four feet. A small human at 5’2” would have a stride length as short as 18”. For a 3’11” elf, that could mean a 14” stride, meaning the 10 minutes of walking a human would do could add another 3 minutes of walking every hour!

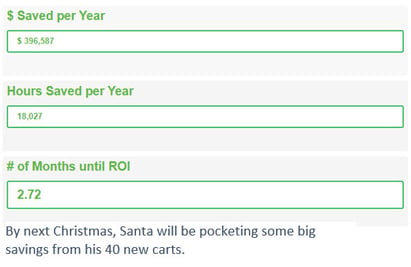

If a 3’11” elf could process wrap and label 30 pallets in 20 minutes walking to a printer between each one, then it would take 1,944 elf-hours to load all 5,833 trailers. If Santa invested in 40 carts to eliminate the walking, then the trailers can all get loaded in only 1,523 hours, saving 421 hours!

If Santa needs to leave at 4pm on Christmas Eve, then the Elves can work on building toys right up to midnight on the 22nd, then run five straight eight-hour shifts to get all the trailers loaded in time for Santa’s 4pm departure on the 24th!

Better yet – Santa saves. Santa saves BIG. If he were to research the savings on our online calculator he would not only get the financial benefit from the investment, but would very likely improve the health of his elves and reduce worker’s comp claims from fatigue on the floor.

The Best Way to Spread Christmas Cheer…

Actually, most of our team is unlikely to “sing loud for all to hear” – at least in front of clients.

Actually, most of our team is unlikely to “sing loud for all to hear” – at least in front of clients.

But the team at Newcastle Systems wants to wish everyone – customers, suppliers, partners and resellers – a wonderful holiday season and continued success in 2020.