Manufacturing Execution Systems (MES) have been around for quite a while now, and there are hundreds of choices out there for MES solutions. As MES covers a very broad and often loose range of added-value topics, it is rare to find any two MES solutions that offer the same scope of functionality. This is especially true given the rapid progress of related IT technologies, for example, Industrial Internet of Things (IIoT) and initiatives such as the “Smart Factory”. It is therefore important to understand the principles and technologies behind MES so that it will work for your needs and requirements, rather than the other way around.

Approaching MES

The best approach to MES is to find out the key business goals that need to be achieved and then work backward. This avoids the endless wading through technical specifications that provide a myriad of functionalities that may appear confusing until the context of what is needed is clarified. In reality, many MES functions may be irrelevant for the immediate specific need, and so this helps a great deal with the selection process, though of course considerations need to be remembered for potential future phases.

The selection of MES software and supporting hardware technologies should pave the way towards a single platform that will meet longer-term targeted goals without the need for replacement. The cost of an MES system is not simply the cost of software and hardware but is mainly the investment in the changes that an MES driven operation will make to allow the MES to work effectively. Different MES systems effectively prescribe a “best practice”, the fundamentals of which, when compared to both the current and targeted operation, must be considered.

The cost of change and cost of ownership can be more significant than the capital purchase.

MES & ERP

MES will sit together with other existing and evolve factory control systems. Almost every factory has an Enterprise Resource Planning (ERP) solution, which in many cases appears to have overlapping functionality with MES. ERP however, typically is orientated towards logical planning for the factory, whereas MES is more concerned with the physical operation. ERP by itself does not have clear knowledge about individual manufacturing processes and capabilities, such that there is an intermediate process required to “translate” the ERP plan into something that can be executed, which without MES this is most often done manually. With MES, information from ERP regarding requirements is used as the basis with which to create specific production operations that MES will then manage. MES, in turn, provides information of greater accuracy about operations back to ERP, which can be used to enhance the abilities to plan next time around.

The relationship between ERP and MES is a key factor for consideration, including where is the point of exchange between the two systems. The simplest way is to define the roles of the two systems according to their strengths, which is most often that the planning is done simply and logically within ERP, while the physical tasks that take place in production are managed by MES in a live and detailed way.

Starting Out

The starting point when considering MES is the endpoint of production, the completion of products ready for shipping. The critical metric here from the customer perspective is on-time delivery. For the manufacturing operation, it is the cost of manufacture as well as the capacity of the facility. Capacity is dictated not only by the range of equipment in place but also how it is utilized when faced with the inevitable requirement of changing from one product model to another. The degree of flexibility of both automated and manual production operations dictates the overall effectiveness of the facility when making a high mix of products.

To determine the overall capability to meet delivery goals where many product types are being produced simultaneously is a very difficult calculation. This is the first potential value of MES. Having a computer-based digitalization creates visibility of the status and performance of processes at all times and in all situations, brings opportunities for improvement in the flow of production and even in the assignment of work-orders.

The live tracking of final products and sub-assemblies is a cornerstone of MES. A unique ID, as a label or for example, an etched barcode, can be used to track each production unit on its journey through the factory.

Simple MES Operation

The unique ID of each production unit is read at each key station, providing several key related values. Firstly, MES processes information about each event, in this case being able to show the location of every production unit. Using the timings of each reading, MES can show visualizations of the flow of production units regarding graphs showing representations of “Key Points of Interest” (KPIs) that help production management and engineering understand the performance of manufacturing. For example, bottleneck processes can be identified where products are queuing before a workstation. Starvation of operations can be found where operators are idle as they wait for the next production unit to arrive. Production units that fail test or inspection processes and need re-routing to repair stations can also be seen, as can the disruption that it causes to the main production flow. Details of efficiency, productivity, Overall Equipment Efficiency (OEE), etc. can all be determined from analysis of the throughput of production units through each production process and travel time between them.

The tracking of production units in this way leads to other benefits. MES can also ensure that when the ID of a product is read, conformance against work-order is assured, such that each production unit can only go through each process in the correct sequence, including consideration of repair loops. This ensures that no production process, or more crucially, a test or inspection operation, is missed. MES systems that are linked with engineering data preparation systems can also ensure for example that the appropriate operation standard and setup documentation for operators will exactly match the product being made, including, for example, any revision variation or material substitutions.

The ability to show documentation electronically eliminates several opportunities for issues associated with paper-based management. Data from automated and semi-automated production processes, such as a test result, can also be collected and attributed against each production unit so that a history of production can be made in the form of production unit traceability. The complexity of this depends on how much data can be obtained from machines and how much time is available for manual operator input. The machine connectivity and user-interfaces are a critical part of the success of MES. The ability to interpret data from many different machines and the ability to gather manual operator input in a consistent and managed way are clear differentiators of MES capability. With manual processes, MES interfaces are personal to the operator, rather than necessarily fixed to an operational location. It is quite usual in manufacturing that there are dedicated physical processes to certain products, for example, functional test, such that not all processes need to be manned simultaneously. The ability of MES to function in a mobile environment rather than being installed at fixed stations is critical in today’s dynamic factories.

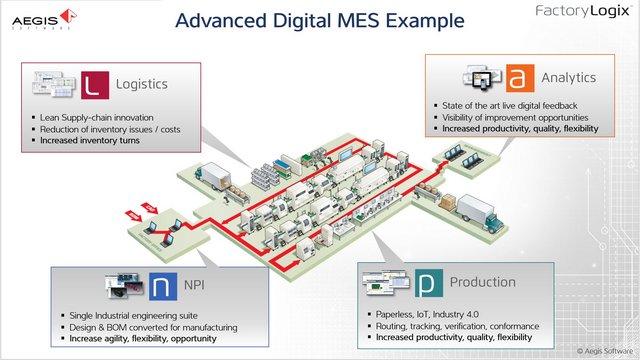

This simple “first phase” look at the top level of MES provides fundamental visibility of the operation, knowledge about how it is working while highlighting where improvements could be made. There are however many underlying factors that need to be considered to work out how to approach any changes, and what effect those changes may have. Production has many dependencies on other aspects of the total factory operations. These include material preparation and logistics, quality management, engineering data preparation, management of key tools, resources, and of course people. The scope of MES therefore normally goes into deeper aspects of factory management to include support for these dependent processes, such that causes of symptoms seen in the production flow can be addressed, as well as the optimization and improvement of the dependent processes themselves.

In the second of this three-part series introducing MES, we will look at how and where MES systems work at managing dependent resources.

About the Author:

Aegis Software is the leading provider of innovative software solutions to improve speed, control and visibility throughout manufacturing operations. Founded in 1997 by two manufacturing engineers, Aegis has over 17 years of experience providing world-class software to customers around the globe. Our install base spans more than 1700 factory sites across the electronics, medical, automotive, military and aerospace industries.

Aegis Software is the leading provider of innovative software solutions to improve speed, control and visibility throughout manufacturing operations. Founded in 1997 by two manufacturing engineers, Aegis has over 17 years of experience providing world-class software to customers around the globe. Our install base spans more than 1700 factory sites across the electronics, medical, automotive, military and aerospace industries.