If you have always been a big fan of following futuristic trends, then twenty years ago you might have assumed that by this year peel and stick labels would be a thing of the past and your products and packages would be engraved by lasers. The reality is that as supply chains have gotten more sophisticated and Ecommerce continues on its decades-long growth trend, “labels” have not only NOT gone away, they are more prolific and ubiquitous than ever – and more important than ever.

Aside from a growth trajectory with no visible end, here are some of the labeling trends we think are important to be aware of today.

Renewed Importance to Supply Chain

The pandemic of 2020 strained and sometimes broke supply chains in some industries that are still trying to recover today. One thing (among many) that saw a lot of renewed – and first time – interest was in labeling, including RFID tags. With the chaos that defined so many businesses' distribution processes in 2020, and the need to make EVERY unit and part count under high demand, accuracy issues, clarity, speed and more all called for improved labeling practices. According to a recent survey conducted by Loftware, 40% of the respondents in their annual “Top 5 Trends” survey said their appreciation for labeling increased during the pandemic, with a whopping 70% indicating it was important to provide access to labeling to suppliers – a key transition where mistakes can disconnect lead to bigger issues downstream.

A big part of this renewed “appreciation” focuses on upstream suppliers because the pandemic revealed too many “blond spots” in the process that created surprise on the Receiving dock and the other big part of it involves the giant jump into Ecommerce so many businesses felt forced to commit to for the first time that increased their need for shipping labels by a factor of ten or more. Where they used to label a single case being shipped to a retail store, they now need a label for every single item in that case on a package going directly to the consumer.

Integration with Marketing and Customer Engagement

What happens to your product once it leaves your warehouse or the retail shelf? While we have often emphasized the importance of the packing and shipping process as “the last person to see the product before the customer gets it” along with the implications that come from any potential mislabeling at that point, the labels ON the product are beginning to matter more.

What happens to your product once it leaves your warehouse or the retail shelf? While we have often emphasized the importance of the packing and shipping process as “the last person to see the product before the customer gets it” along with the implications that come from any potential mislabeling at that point, the labels ON the product are beginning to matter more.

“E-Labeling” is the term used for labels that can connect the product to a wider portfolio of information that can improve the user experience. It has become an avenue for the once under-utilized QR code, which has found its niche in applications like this. By including a QR code label on a product you can direct users more quickly to support information, accessories, replacement info, user manuals or more.

The advantages of using this approach are amplified by being strategic about where the label is visible and thinking through the use cases where it would be most useful.

Digitization and Personalization

While it is not a NEW thing, nor even a new “trend”, digital is now, more than ever, the focus of everyone in labels. Improvements in quality, increased substrate, color choices, label management software and quicker lead times all accelerated last year and more than ever align digital with customer demand (This is something that is happening concurrently in every segment of the graphic arts and is impacting packaging too).

According to the same Loftware survey referred to above, 50% of respondents reported seeing more demand for personalization in both packaging and labeling. Given that Marketing has now made personalization the norm, it is not surprising that a customer who saw all the messages tailored to their preferences and name would eventually expect the products they buy from that messaging to be personalized too.

The concept of a “digital identity” will become commonplace – where the data you have for your customer will be expected to be used on ALL levels of engagement with them.

“Lean Labeling” and Waste Reduction

Finally, the explosion in label usage is starting to bring some attention to one of those problems most facility managers don’t know they have – label waste. This is one of those overlooked issues that result from the relatively infinitesimal cost of a single label. But when you think about a business that runs a full sheet of 12 labels through a laser printer to print the 8-9 needed at the moment, then repeats that step hundreds of times a day, then the waste really adds up. Other waste that results from labeling processes are also often unmeasured and unnoticed:

Finally, the explosion in label usage is starting to bring some attention to one of those problems most facility managers don’t know they have – label waste. This is one of those overlooked issues that result from the relatively infinitesimal cost of a single label. But when you think about a business that runs a full sheet of 12 labels through a laser printer to print the 8-9 needed at the moment, then repeats that step hundreds of times a day, then the waste really adds up. Other waste that results from labeling processes are also often unmeasured and unnoticed:

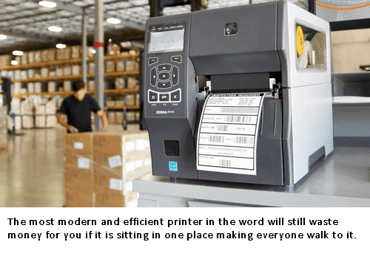

- Wasted steps walking back and forth to a stationary printer

- Wasted time from changing label materials

- Wasted time from manually switching label designs

- Disparate designs not centrally managed

The Loftware survey indicated that 86% of respondents see the benefits of managing labels remotely from a central location and 91% “believe that maintaining one standardized labeling solution across their enterprise, rather than managing multiple solutions, provides time and cost benefits“.

While even a few years ago this might have appeared to be a lofty ideal that was not quite operable yet, but the advent of software like Bartender, powerful and light batteries that allow your printers to become mobile (and enable printing where it is needed!) and tools like Mobile Device Management software means that labeling can become be optimized well beyond anything previously imagined.

Our own Kevin Ledversis recently did a webinar on the concept of “Lean Labeling” and in it he shares a number of concepts that you can begin executing today (view the webinar here).

Download The Warehouse Guide to Lean Labeling to start creating better awareness of the label problems you may not see and how to address them.