UPDATE: On Monday, March 29th, 2021, the Ever Given was freed and continued its journey northward, allowing for the passage of over 360 ships that had impacted about 15% of the entire world's container capacity. Bon Voyage!

Last week was the beginning of one of those rare weeks when you could tune into your daily news broadcast and hear your usual news readers interviewing supply chain analysts, shipping company representatives and logistics experts almost every day – a group of professional profiles that you almost never see on the national news!

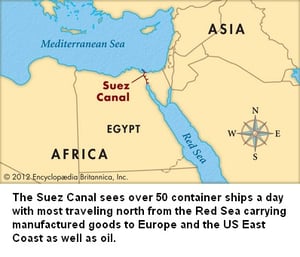

Why? For those who have not been paying attention, the Suez Canal has been completely BLOCKED by a single freighter ship that got jammed up on both sides of the canal while trying to navigate during a severe windstorm.

The importance of this event is far-reaching – it impacts economies in nearly every developed country in the world and indirectly impacts many others as well. With 13% of annual global trade passing through the canal in 2020 via the 19,000 ships carrying 1.17 billion tons of cargo, the impacts are going to reverberate through all supply chains as another 50+ ships get held up waiting to pass meaning at least 400 of them will be idling while you are reading this.

The importance of this event is far-reaching – it impacts economies in nearly every developed country in the world and indirectly impacts many others as well. With 13% of annual global trade passing through the canal in 2020 via the 19,000 ships carrying 1.17 billion tons of cargo, the impacts are going to reverberate through all supply chains as another 50+ ships get held up waiting to pass meaning at least 400 of them will be idling while you are reading this.

Think of something more local that might have a similar effect. Imagine a national retailer during holiday season supplying its 850 stores from six massive Distribution Centers it has around the country – and then imagine one of them has to shut down for a week with all of its contents locked inside with nothing going in or out. Now imagine the trucks that were arriving that day to unload, the empty ones waiting to be loaded, and the store shelves for that 13% of the stores being served going empty over the next week forcing shoppers to abandon your brand. That’s 110 stores losing sales, customers, and even employees after a week.

The incident with the Ever Given (which is being tended to by eight tug boats, dredging machines, the US Navy and more as we write this), is an example of the importance of finding the choke points in your supply chain and ensuring you don’t have a catastrophic weakness like this yourself. What are some of the key places to look for these “choke points”?

Common Supply Chain Choke Points

First of all, we should acknowledge that the events in the Suez Canal are a rarity. It has been open since 1869 and there is no known example of this happening in the last 150 years. This week might have been made more predictable by the ever-growing size of container ships. The Ever Given is one of the newer “New Panamax” class of ships that is 1300 feet long and can carry 20,000 containers. To understand how this is a newer danger to the canal – before the year 2000, container ships never exceeded 1000 feet and the canal is only 984 wide.

Technology changes mean that choke points in your supply chain that you did not have 10 years, or even 2 years ago, may now exist where you thought they did not. Here are a few to review:

- Warehouse Management Systems and related systems – there are few technologies that change as fast as software. We still see manufactuers and retailers who still do not have some basic features that are now considered standard in their software stack. For example, backorder functionality. A key element of avoiding lost sales means that even when you don’t have a product, you can tell your customer both if and when they can get it, and even reserve one for them too. When a customer goes online week after week and sees “out of stock” and you can’t tell them when you will have more (even if there is more coming), then you will be losing customers.

- Single Source Suppliers/Supplies – this is a choke point we can relate to in our own manufacturing process, and one that is often not easy to address. Lithium, the key element in our proprietary PowerSwap Nucleus batteries, is far more plentiful outside of the US and the processing of it and manufacturing of it into battery cells is dominated by Asian manufacturers. The boom in rechargeable battery power across a wide spectrum commercial and consumer applications has made the sourcing of Lithium and rare-earth metals that are also part of the this technology boom a potential choke point. For resources like this, the “choke point” aspect may not always be scarcity, but price.

- Your Own Warehouse – How does your warehouse make itself a choke point? By not constantly re-evaluating processes and improving efficiency with the goal of increasing your turns. The more turns you create the more productive each cubic foot will be. If your competitor is averaging five turns when you are getting three, then you will need to acquire and build out more space just to keep up with the same volume. If you can’t afford to do that you now have a choke point on your sales volume, and even if you do, it means you will be generating either lower margins for your business or higher prices for your customer.

- Lack of Process Improvement – even if your warehouse is generally a smooth-running operation at both peak and non-peak seasons, breaking down individual processes and re-evaluating them one at a time (in addition to looking at the big picture) is an important part of avoiding choke points. As seen on this page frequently, Receiving is a common culprit as even some of the smoothest operations that pick, pack and ship above their industry standard can have delays and lost product happen at the Receiving dock. The impacts of a slow intake process in Receiving reverberates outside the warehouse with trucks that may be idling – and charging you for the time.

There may not be a Warehouse equivalent to blocking to Suez Canal, but the first lift truck operator here may have come very close!

What’s The Best Place to Start?

While this may differ for every business, we generally recommend starting at home, and working your way outward. First take a deep dive into your Receiving process or picking process, for example. How many steps does the staff need to complete the process? Are there wasted touches, mistakes, or backups that can not be explained? Having an expert’s knowledge on your own processes and technology first then gives you the information you need to ask the questions you’ll want answered on the outside of your business from your suppliers and vendors.

And by all means, let’s hope a sandstorm never blows a lift truck off-course and block your Receiving Dock for a week!