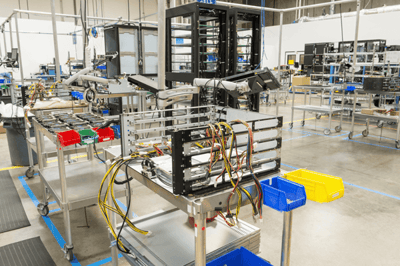

Speed, safety and efficiency are important to running a successful manufacturing floor. The more efficient workers are on the floor, the quicker products can be finished and sent to their destination.

The major opponent to efficiency on the floor is, of course, waste. Waste comes in many different forms, and all of them are a liability to the overall effectiveness of a manufacturing floor.

Successful operations managers need to find solutions that cut down on waste and improve processes on the manufacturing floor, and one solution to be considered is mobile power.

Mobile power is a movable, flexible, ergonomic and battery-powered workstation that allows manufacturing floor workers to hold and power computers, printers, scanners and more on a portable workstation that moves along with them throughout their tasks on the floor. Mobile powered carts provide many benefits and make an immediate impact once they enter a manufacturing facility. Most importantly, the workstations reduce waste in a major way. What kind of waste are we talking about? Some waste is hard to see as it has always been ingrained in everyday activity on the manufacturing floor. Here is an outline of the waste that mobile powered workstations reduce.

- Wasted steps: Yes, walking is very much a form of waste on the manufacturing floor. Workers on the manufacturing floor are walking all day, and each unnecessary step is wasted time and energy. When mobile powered workstations are implemented on a manufacturing floor, steps are greatly reduced as workers no longer need to walk to fixed printers or computers—everything they need is right with them, and its mobile. Check out the potential savings with an ROI calculator, at tinyurl.com/y8rfjurp.

- Wasted touches: Minimizing touches of all goods entering and exiting the manufacturing floor is essential in reducing waste. Every touch is costing a manufacturing floor time, which in turn costs money. Mobile powered stations condense all equipment into one moveable spot, so any labeling and tedious measures can all be done in one spot without unnecessary process steps.

- Wasted equipment: Mobile powered workstations let manufacturing plants achieve the same level of output, with fewer pieces of equipment. Printers, scales, test equipment and software can all be included in a mobile powered workstation.

- Wasted staff turnover: Work on the manufacturing floor is a tough, physical job. Add in the pressure to do everything in a timely manner and you have jobs with a high turnover rate. Adding in mobile powered workstations will help staff members complete their tasks faster with less walking, both advantages in staff retention goals. The workstations also enable operators to access real-time information anywhere in the facility because of the mobility of the workstations, a major asset when tracking production.

Cogmedix, an original equipment manufacturer for medical and dental devices, recently embarked on a companywide process improvement initiative that included 10 ergonomic mobile powered workstations to hold power touchscreen LCDs, small printers and scanners.

The issue Cogmedix faced was that their technicians were walking to static computer stations to log in and out of work orders. At busy times, lines would form at the computer stations with associates aiming to transact their work orders. Medical device manufacturing regulations require that work instructions and device history records must follow the associate and manufactured product at all stages through production. Because of this, mobility became important. A corded computer station would result in unplugging and plugging them into the next outlet available, which was very inefficient and contributed to waste throughout the process.

The clear solution for Cogmedix was mobile power. Technicians at Cogmedix now have full-screen access to ERP and other information systems on the production floor, meaning that there is no more paper and no more wasted steps.

Article originally published in the May 2018 issue of Smart Manufacturing.